Hands that Make Harris Tweed®: PART 4

22nd June

The Hands that make Harris Tweed®

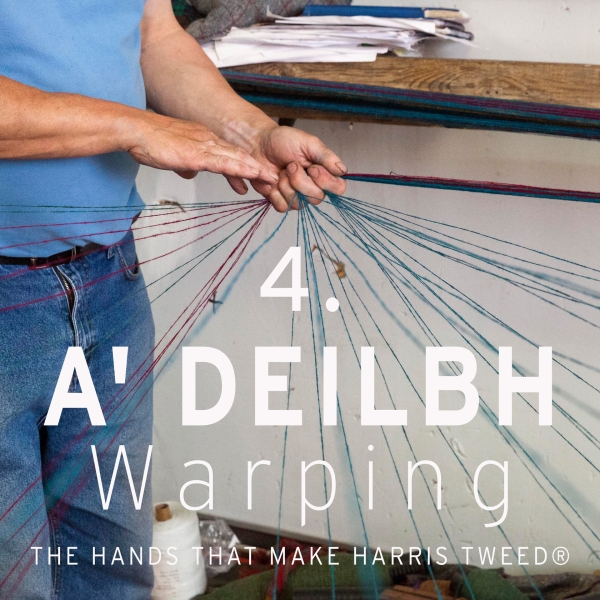

Part 4: WARPING

A’ Deilbh

/dʲelev/

This week, our ‘Hands that Make harris Tweed®’ series is about one very important and skilled part of the process; warping.

For each double width tweed, up to 1400 warp threads are arranged in very specific order and wound onto a beam, ready to be delivered to the weaver’s home.

A independent weaver, who creates their own single width Harris Tweed® patterns and designs, will do this part of the the process themselves. Some independent weavers do this at home in their weaving shed, and some in a shared space big enough to hold a warping frame.

It’s a highly skilled process and one you really must make sure is done properly before weaving. On that note, you may be able to guess what we’ll cover next week, Part 5 of our Hands that Make Harris Tweed® series.

Photograph taken by Jackson Tucker Lynch

Read more about the full Harris Tweed® production process:

https://www.harristweed.org/the-process/